Providing Metal Injection Molding (MIM) Manufacturing for Over 25 Years!

Innovative MIM Manufacturing for Diverse Industries

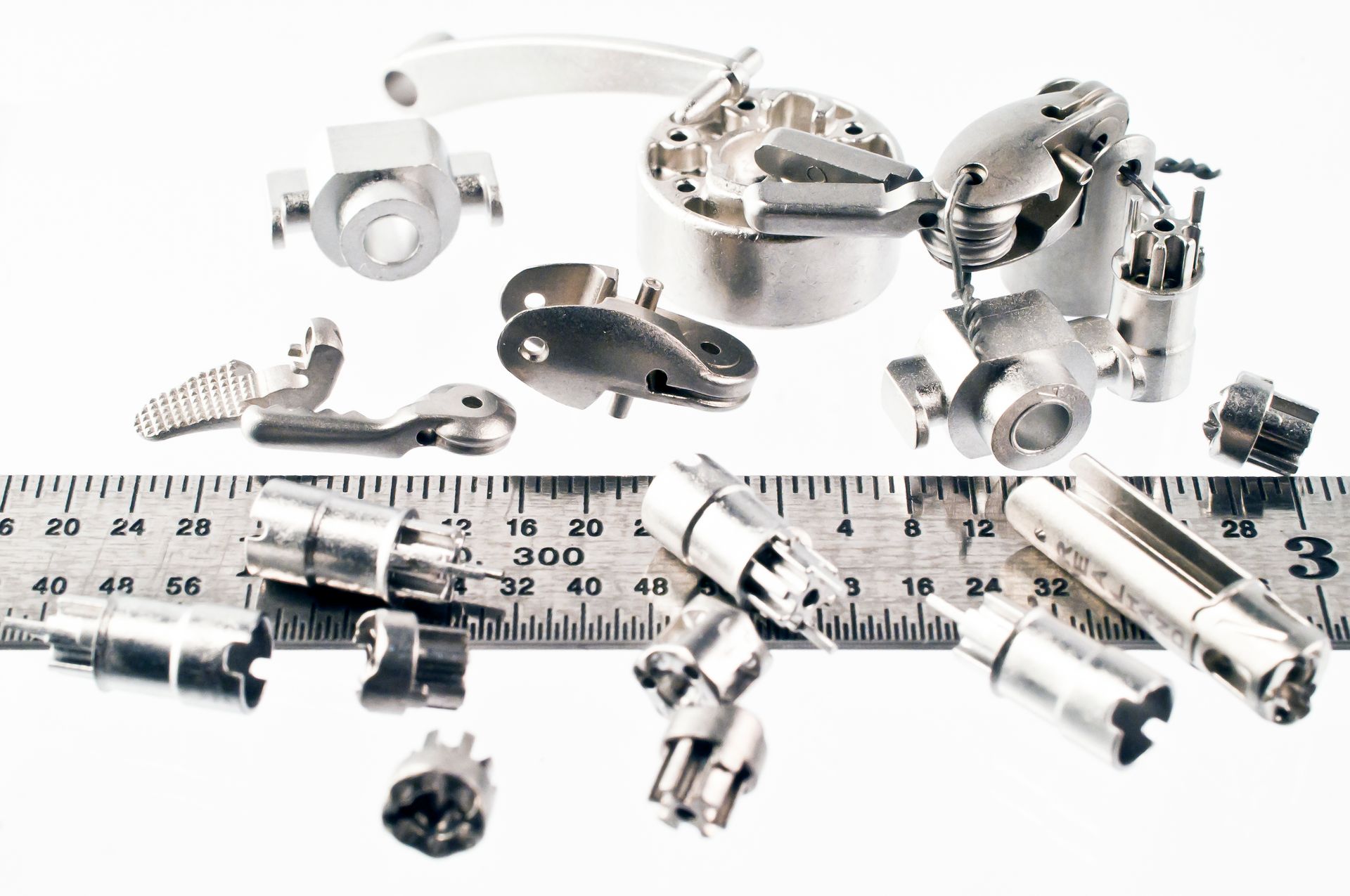

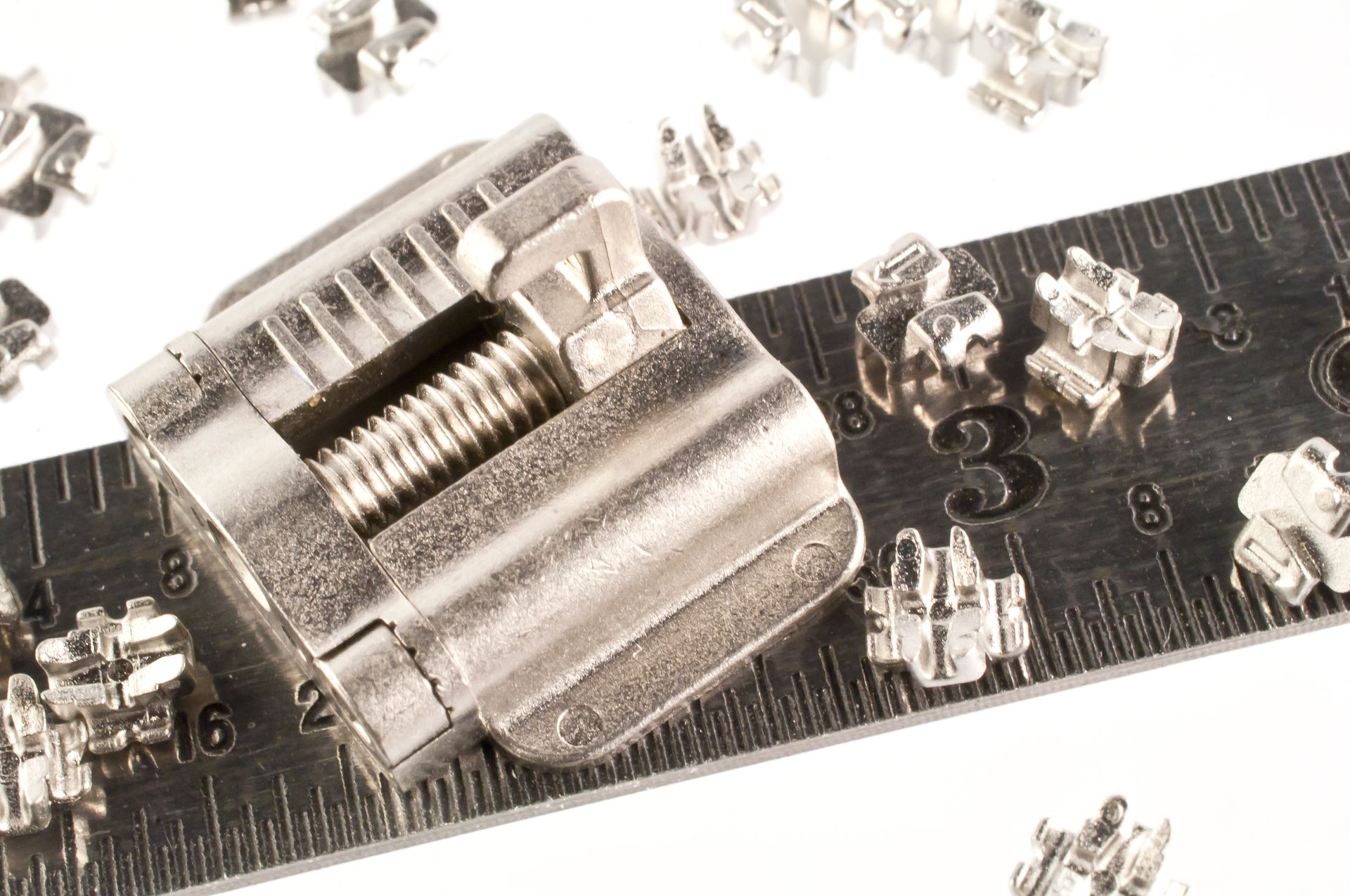

Welcome to Smith Metal Products, a leader in metal injection molding (MIM) manufacturing with over 25 years of experience. As a division of Plastic Products Company, Inc., one of the largest employee-owned molders in the United States, we specialize in delivering highly engineered solutions to meet your manufacturing needs. Our expertise, state-of-the-art equipment, and proprietary processing technology ensure top-quality MIM and CIM products that exceed expectations. Explore our range of material systems and discover the flexibility and innovation Smith Metal Products offers. Contact our Center City, MN, facility today! Click here to get started.

PROUDLY MADE IN THE USA

Advanced MIM Solutions and Technologies

Explore Our Expertise and Opportunities

Why Choose Smith Metal Products for Your MIM Needs

Our advanced MIM technology offers unparalleled precision and cost-efficiency, allowing for the production of complex geometries that are often unattainable with traditional methods. With a commitment to quality, state-of-the-art facilities, and a dedicated team of experts, we ensure your parts meet the highest standards. Whether you need solutions for firearms, medical devices, electronics, or industrial components, Smith Metal Products delivers reliability, innovation, and excellence.