Learn About Smith Metal Products

Quality Standards and Capabilities

Quality Assurance

Smith Metal Products strives to achieve the highest precision MIM components. We begin with the attitude that we are not simply supplying components. “We are in the business of making our customers successful.”

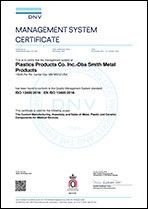

We are proud to be ISO 9001:2015 Certified and ISO 13485:2016 Certified. These standards encompass all phases of the manufacturing process. Our controlled documentation system assures you of consistent set-up and repeatability on every production run.

Smith Metal Products has announced it has received the

Federal Firearms License (FFL) and added to its other accreditations that include ISO 13485, ITAR,

and ISO 9001:2015. This reinforces our quality commitment to producing components with unbeatable levels of precision, strength, and durability at competitive prices.

MIM Molding Process

Making high quality parts that others say can’t be done is where Smith Metal Products outperforms other sources. Our MIM capabilities are a turnkey program that includes: Design for Manufacturability, management, sourcing, manufacturing, value-added secondary processing, to point-of-purchase packaging.

Smith Metal Products MIM Molding processes are built around the BASF Catamold production process and equipment. As with all MIM processes, your parts begin when the metal powder is suspended in a binder or feedstock, which is then injection molded into a tool. If 100% density is required parts can be Hot Isostatic Press (HIP) treated.

Learn more about MIM in our complete design guide.

CONTACT DETAILS

Phone: (651) 257-3143

Email: sales@smithmetals.com

Address: 15045 Per Rd, Center City, MN 55012

CERTIFICATIONS

- ISO 9001

- ISO 13485

- FFL

- ITAR

Write your caption hereButton

Write your caption hereButton Write your caption hereButton

Write your caption hereButton