Metal Injection Molding (MIM) Process

MIM Overview

Engineers think of injection molding as a plastic-forming technology using polyethylene, polystyrene, glass-filled nylon, and similar materials. Metals and ceramics have several desirable properties when compared with plastics. They are stronger, tougher, stiffer, have better chemical resistance, and offer significant latitude in electrical and thermal conductivity, magnetic response, wear behavior, and operate to high temperatures. MIM is a synergistic combination of the performance properties associated with inorganic materials and injection molding associated with plastics. Most applications for powder injection molding are in ferrous metals, especially stainless steel.

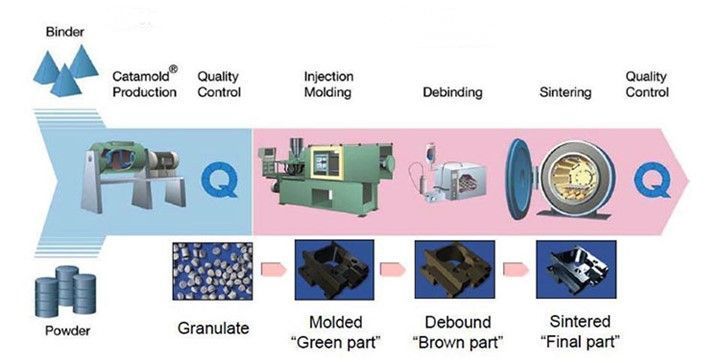

In our metal injection molding (MIM) process, small metal powders are molded in the desired shape using a thermoplastic binder. Binders can be as simple as paraffin wax (candle wax) but we use a mixture of several engineering polymers. The binder softens and melts on heating and then solidifies in the mold to hold the particles into the desired shape. After molding, the binder is removed, and the shaped powder is sintered to attain the target properties. A schematic of the SMP process is illustrated below. The polymeric binder bonds the particles during the shaping process and is extracted as the particles are heated. Once the polymer is extracted, the porous powder structure looks like the molded shape, but it is weak. However, when the powder is heated to a high temperature, the particles bond and densify due to capillary attraction, in what is called sintering. There is a tremendous strength gain in sintering, to the point that the sintered solid is essentially indistinguishable in strength from wrought metal. So, in MIM, the plastic or polymer is only a transient phase, added to help the metal particles flow and fill out the mold.

The MIM process has many variants, reflecting different combinations of powders, binders, molding techniques, de-binding routes, and sintering furnaces. However, all variants share three technology areas:

- Feedstock; powders, binders, mixing

- Molding; rheology, tool design, machine/press operation

- Thermal processing; de-binding, sintering, heat treatment

-

SMP Process Schematic Illustration

Button

CONTACT DETAILS

Phone: (651) 257-3143

Email: sales@smithmetals.com

Address: 15045 Per Rd, Center City, MN 55012

CERTIFICATIONS

- ISO 9001

- ISO 13485

- FFL

- ITAR

Write your caption hereButton

Write your caption hereButton Write your caption hereButton

Write your caption hereButton