Smith Metal Products MIM Resources

Ownership

Smith Metal Products is a division of Plastic Products Company, Inc. which is one of the largest Employee-owned molders in the United States. Since 1997 the company has offered highly engineered solutions to customers plastic molding manufacturing needs.

With plants in several states, multiple process choices, over 250 presses, and an a la carte menu of services ranging from design through order fulfillment, PPC can provide customers with the best possible plastic products.

Smith Metal Products Affiliations

Smith Metal Products is a proud member of the Metal Injection Molding Association. We participate in MIMA educational activities and technical conferences and utilize MIMA courses, facts, data, and standards fundamental to the application of products and technology.

The Metal Injection Molding Association is a constituent of the Metal Powder Industries Federation.

Metal Injection Molding (MIM) is a Powder Metallurgy: A Green Technology

The net-shape capability of MIM is the primary advantage in the process, but there is also no waste in the shaping of parts. Being sustainable is important to us at Smith Metal Products.

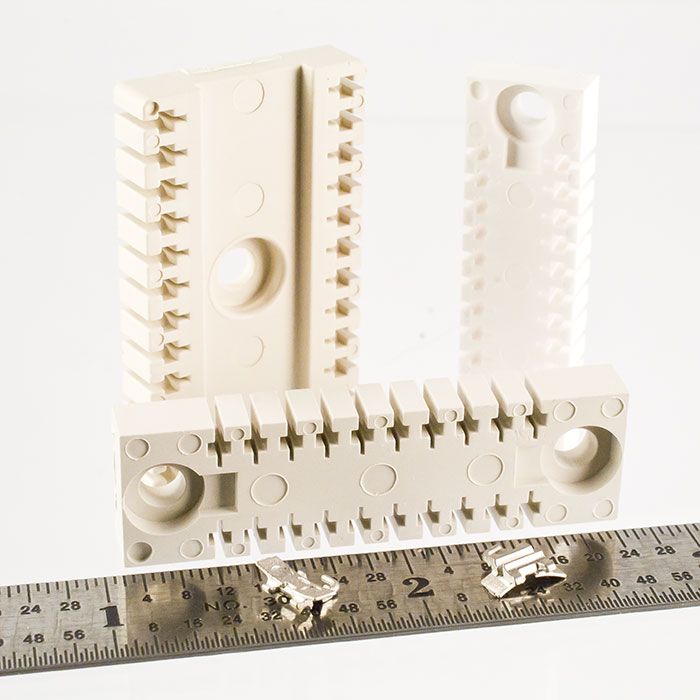

Examples

-

Button

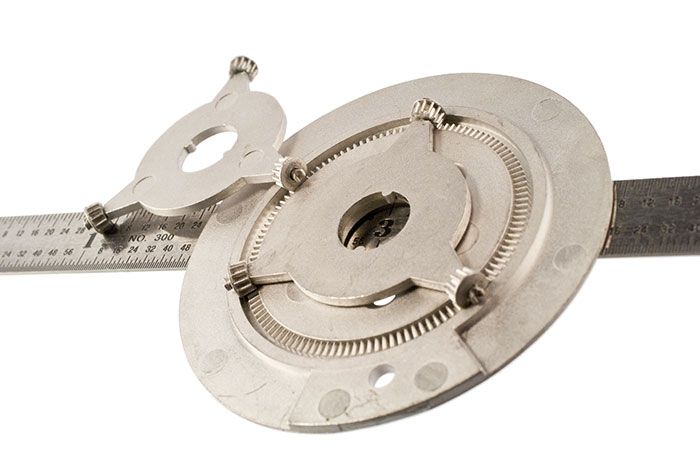

Archery

-

Button

Fluid Delivery

-

Button

Hinge Components

-

Button

Ceramic Insulator

-

Button

Electronic Fiber Package

-

Button

Camera Component

-

Button

Dental Braces Orthodontic

-

Button

Dental Repositioning Orthodontic

-

Button

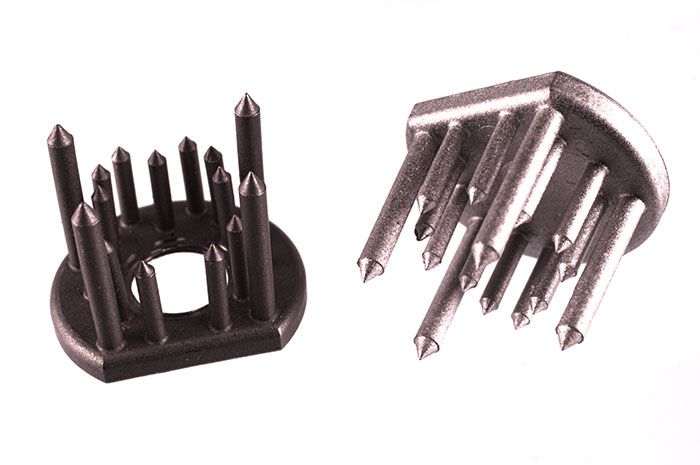

Medical Laparoscopic Grippers Articulation

-

Button

Medical Device

-

Button

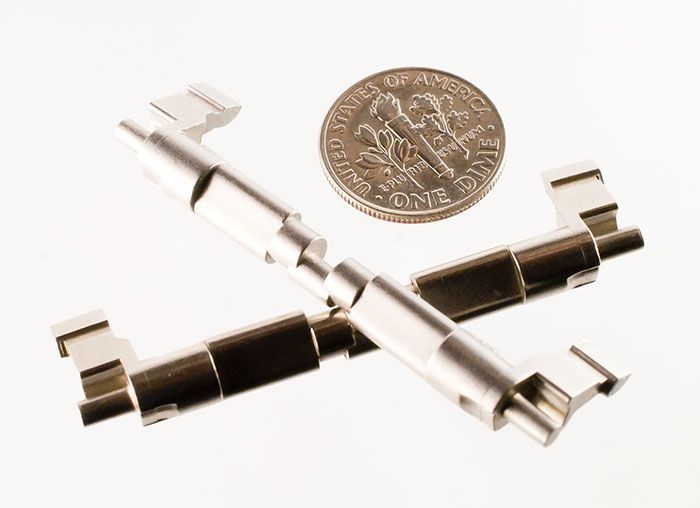

Firearm Components

-

Button

Decorative Metal Ring

-

Button

Latch for Electronics

-

Button

Hinge for Electronics

-

Button

Medical Parts

-

Button

Surgical Medical Parts

Write your caption hereButton

Write your caption hereButton Write your caption hereButton

Write your caption hereButton

Definitions

The following definitions first give the word or phrase commonly encountered in MIM, followed by a brief sentence or two on how they apply.

-

Acicular Powder

Needle-shaped particles are good for de-binding strength, but they are generally detrimental to the MIM forming process since they resist flow in molding.

-

Adiabatic Forming

The use of a frozen powder-water feedstock that melts and flows under pressure but refreezes when pressure is released.

-

Admixed Powder

A small, discrete powder mixed with another powder for lubrication, bonding, or alloying. One common means of forming MIM alloys or composites is via admixed powders.

-

Agglomeration

A tendency for small MIM particles to stick together and appear as larger particles. It is a common problem with nonconductive powders such as ceramics, especially as the particle size decreases.

-

Air Classification

A most common means to separate specific size classes of powders by differential settling in a high-velocity air stream or cyclone.

-

Alloy Powder

A powder in which each particle is composed of the same mixture of two or more constituents, especially common in gas or water-atomized powders such as stainless steels.

-

Alumina

The compound of aluminum and oxygen Al2O3, which is the most common material used in ceramics, is often used as a furnace lining, hardware, or setter support for sintering.

-

The angle of Repose

The angle from the horizontal plane that a pile of loose powder will assume when freely poured through an orifice, providing a measure of the interparticle friction and ease of shape retention during debonding.

-

Apparent Density

The mass of a unit volume of powder in the loose condition, usually expressed in g/cm3. For MIM powders, it is often 50% of the theoretical density of the material.

-

Aspect Ratio

The ratio of the maximum particle dimension to the minimum dimension.

-

Atomization

The dispersion of molten material into droplets by a rapidly moving stream of gas or liquid (usually water) or by centrifugal force. The droplets solidify into particles.

-

Atomized Powder

Alloy or metal powder produced by the disintegration and subsequent solidification of a molten metal stream.

-

Attrition

A mechanical milling or grinding process that typically employs a stirred or tumbled container filled with small balls that act as a crushing medium. The tumbling action causes repeated collisions against particles mixed with the balls. The process is widely used for deagglomeration, partial alloying (W-Cu, WC-Co), and particle size reduction in ceramics.

-

Austenite

The face-centered cubic crystal structure of pure iron that is not stable below 910°C. However, with alloying, this nonmagnetic form of iron can be stabilized at room temperature and even cryogenic temperatures; austenitic stainless steels are a common example where sufficient nickel is employed to stabilize the nonmagnetic phase at room temperature.

-

Barrel

The heated portion of a molding press that melts the binder in the feedstock so it can flow through the nozzle and into the mold to fill the cavity. The barrel holds the feedstock under pressure as it heats and melts the binder material.

-

BET Surface Area

The specific surface area as measured by gas adsorption according to the Brunauer, Emmett, and Teller theory. Widely used in the characterization of ceramic MIM powders and expressed as square meters per gram, m2/g.

-

Bimodal

A particle size distribution exhibiting two modes (mode is the most common or most frequent) sizes. Although such a powder can result from mixing two different particle size distributions, some powder production techniques naturally produce this distribution. Its main advantage is that it produces higher solids loading in MIM feedstock. It is common to use trimodal mixtures in ceramic MIM.

-

Binder

The polymer mixture that provides lubrication and strength to the powder. It is critical to the feedstock fluidity during molding and to the strength of the molded component. The binder is evaporated during de-binding and sintering. Binder formulations generally fall into a few classes, but exact formulations are usually proprietary. The binder chemistry impacts the de-binding process.

-

Bingham Flow

Viscous flow of a feedstock with initial yield strength, meaning the stress must exceed the yield strength prior to initiation of viscous flow.

-

Blending

The thorough intermingling of powders of the same nominal composition, for example, the combination of water-atomized and gas-atomized stainless steels.

-

Brown State

A term originally used to describe a ferrous MIM component following de-binding by slow heating in air to remove the polymer, where oxygen caused the iron to oxidize into a rust-colored component.

-

Burn-Off

The removal of the polymer binder via preheating prior to sintering.

-

Capillary Rheometer

A device for measuring viscosity by applying pressure on molten feedstock and determining the flow rate dependence on applied stress as the feedstock is pushed through a small capillary tube. It is useful in determining feedstock flow and homogeneity.

-

Carbo-Nitride

A heat treatment in a nitrogen and methane atmosphere that causes both carbon and nitrogen to diffuse into the steel surface for strengthening and hardening.

-

Carbon Control

A measure of the ability to remove the MIM polymer without contamination of the powder. Carbon control is quantified by the final carbon level and the uniformity of that level between parts or over subsequent operations, fabrication days, or feedstock batches. For some materials, the desire is no final carbon (austenitic stainless steel, alumina, titanium), while others require a precise final carbon level, and in the extreme, cemented carbides and silicon carbides require very high carbon levels.

-

Carbonyl Powder

Predominantly an iron powder, but may also be nickel. These powders are prepared by the thermal decomposition of a metal carbonyl molecule. The resulting particle size is typically in the size range of 1 to 10 µm. The particle shape can be spherical, agglomerated, or highly angular.

-

Carburization-Decarburization

Two events critically related to carbon control since the addition of carbon to a material occurs by carburization from binder or atmosphere sources, while decarburization occurs by reacting carbon in the material with hydrogen, oxygen, or carbon monoxide.

-

Case Carburize

A post-sintering heat treatment aimed at the diffusion of carbon into the surface of a ferrous MIM compact. The carbon increases strength and hardness.

-

Catalytic De-binding

The partial removal of the polymer via heating in an atmosphere containing an agent that induces depolymerization. The classic process involves the extraction of polyacetal using a nitrogen atmosphere doped with nitric acid.

-

CCIM

Cemented carbide powder injection molding, where the inorganic phase in the polymer binders is predominantly a mixture of cementing phase (cobalt is typical) and a carbide (tungsten carbide is typical); a subset of powder injection molding (MIM).

-

Cemented Carbide

A solid composite consisting of a metal carbide and a binder phase, usually cobalt or nickel aluminide. The composite is formed by liquid phase sintering a mixture of the carbide and binder metal powders. The WC composites are known as hard metals in Europe. They are produced by MIM and used for wear, tooling, cutting, or drilling applications.

-

Centrifugal Atomization

The formation of spherical particles by combining a melt with a centrifugal force such that the melt is disintegrated into high-velocity droplets, which spheroidize prior to solidification.

-

Cermet

A composite body consisting of ceramic particles bonded with a metal. Cemented carbides are the most common cermets in production.

-

CIM

Ceramic powder injection molding, where the inorganic phase in the polymer binders is predominantly a ceramic or mixture of ceramics; a subset of powder injection molding.

-

Clamping Force

One of several measures of the capabilities of a molding machine. In this case, the available force for holding the mold together while pressurized feedstock is filling the cavity. If the applied pressure times the projected part area exceeds the clamping force, then the cavity will open or flash during molding.

-

Classification

Separation of a powder into fractions according to particle size.

-

Closed-Loop Feedback Control

A molding concept for precise dimensional control where the pressure inside the molding cavity is monitored during filling and used to adjust the molding machine operation to ensure repeatable filling, weight, and final dimensions. The weight and dimensional scatter in the final parts is greatly reduced by using this control logic as compared to open-loop or adaptive controls.

-

Closed Pore

An isolated pore not linked to the external surface, usually formed in sintering after a component reaches a density of approximately 92% of the theoretical, resulting in the capture of the process atmosphere in the pores.

-

Coarsening

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links. -

Coefficient of Variation

The standard deviation divided by the mean value, giving a nondimensional measure of uniformity in dimensions, weight, or properties.

-

Coining

The final pressing (bending) of a sintered component to obtain a definite surface configuration, flatness, or surface finish.

-

Co-Molding

Also known as two-color molding because of the use of plastics. Two materials are shot into the same cavity from different injector units to form layers, interconnections, or other differences in materials with position in the cavity.

-

Composite

A mixture of two or more powders that form a multiple-phase structure, typically designed to deliver properties that are a hybrid of the constituent properties.

-

Compression

The removal of air from melting feedstock by applying heat and pressure. In a reciprocating screw molding operation, this is achieved by tapering the screw to reduce the space for the feedstock during metering toward the screw tip.

-

Computer-Aided Design (CAD)

The use of a computer program geared to perform stress, fit, dimensional, and other calculations and to allow visualization prior to fabrication.

-

Computer-Aided Manufacturing (CAM)

Computer controlled machines used to ensure proper fabrication and resource utilization; included in the broad category of computer integrated manufacturing and computer-aided manufacturing activities might be inventory control, maintenance schedules, production scheduling, tool path analysis, and cost analysis.

-

Critical Loading

The maximum volume fraction of solid particles that can be incorporated in a polymer binder without forming pores while still allowing flow in normal injection molding situations.

-

Cross-Linking

The formation of bonds between polymer chains to give rigidity and strength to the polymer. Thermosetting polymers that harden on first heating are examples of cross-linked polymers.

-

Cycle Time

A critical measure of molding equipment productivity, it is the time for completion of one molding cycle. It can be measured from the time to start filling to the start of the next fill. Cycle times from a few seconds to 5 minutes are encountered in MIM production.

-

De-binding

A step between molding and sintering where the majority of the binder used in molding is extracted by heat, solvent, catalysis, or other techniques. The de-binding techniques are highly variable between production sites. Thermal de-binding is the most common and the oldest version, but several operations rely on alternatives or combinations of methods.

-

Delamination

The cracking of a molded component, often leading to a hairline crack oriented perpendicular to the ejection direction that is hidden until de-binding or sintering.

-

Densification

The change in porosity divided by the initial porosity due to pressing or sintering. A term loosely associated with property gains in sintering.

-

Density

The mass divided by the volume, usually expressed in g/cm3 (equivalent to Mg/m3) or sometimes given as a ratio to pycnometer or theoretical density.

-

Dew Point

A measure of atmosphere purity based on water content, it is the temperature where moisture condenses out of a process atmosphere. Generally it is assumed a low dew point (low condensation temperature) corresponds to a cleaner atmosphere.

-

Differential Scanning Calorimetry

A means to determine the heat flow into or out of a MIM sample. Usually, it is applied at lower temperatures when the polymer melts, crystallizes, or evaporates.

-

Differential Thermal Analysis

The careful measure of temperature and temperature difference during heating for a MIM material and a reference. Whenever the polymer melts or a phase transformation occurs, the test sample will lag behind the reference, while if there is a reaction, the sample will heat faster than the reference.

-

Dihedral Angle

A microstructure feature associated with phase boundaries in a material. It is evident when a grain boundary intersects with a pore or liquid phase, resulting in a groove in the grain boundary at the point of intersection. Low dihedral angles are associated with high grain boundary energies and unstable microstructures.

-

Dilatant Flow

osity that changes with flow conditions where the mixture actually dilates under stress.

-

Dilatometry

Measurement of dimensional change during thermal processing to determine the sources of sintering densification, phase transformation, or other causes of dimensional control problems. Usually, dilatometry is conducted with a laser or a pushrod that makes contact with the specimen in a furnace. Sintering experiments intended to find the densification temperature for a powder are conducted using constant heating rate dilatometry.

-

Dimensional Control

The repeatability of final dimensions in a MIM operation as measured by part-to-part, day-to-day, and batch-to-batch scatter. Usually quantified by the standard deviation (or a multiple of standard deviations, perhaps as large as six) observed in a dimension as normalized by that dimension, expressed as a percent, for example, a coefficient of variation of 0.1%.

-

Ductility

A measure of the permanent stretching or deformation a material can take prior to failure. Ceramics have no ductility, while materials such as stainless steel and aluminum exhibit large ductilities, often measured at 30 to 60% stretch or elongation prior to failure.

-

Ejection

The final stage of molding is when the powder-binder component is forced out of the die.

-

Ejector Pins

Mechanical pins that are inserted into a die cavity to act as a means to push the molded component out

of the tooling.

-

Elastic Modulus

The material property linking stress and strain. Also known as Young=s modulus or stiffness. In MIM feedstock, it is also important because it determines residual stress and the stress relaxation time in cooling.

-

Elasticity

The spring back of feedstock after ejection from a toolset. Formally, the elastic modulus is the material parameter that links stress to strain, but in MIM, it is largely related to die sticking and dimensional control problems since ejection and de-binding induce stresses that might cause warpage or loss of component precision.

-

Elemental Powder

Powder of a single chemical species like iron, nickel, titanium, copper, or cobalt, with no alloying ingredients.

-

Elongation to Fracture

A measure of ductility, since this is the amount of permanent plastic stretch a material undergoes prior to failure in a tension test. The most common measure used for ductility.

-

Equiaxed Powder

Particles with approximately the same size in all three (perpendicular) dimensions. A sphere formed by gas atomization is the classic example of this desired particle shape.

-

Feedstock

The mixture of powder and binder used in injection molding. Its formulation involves decisions on the powder composition, particle characteristics, binder formulation, mixing practice, and ratio of powder to binder.

-

Ferrite

Various compositions based on iron oxide used to fabricate common magnets, usually containing other metal oxides or ceramics, including zinc oxide. It is also the name given to the body-centered cubic form of pure iron.

-

Ferritic Steel

An alloy based on iron that consists of a body-centered cubic crystal structure. It is the most common form of low alloy steel when slow cooled, but is usually heat treated to form martensite.

-

Filling

The first phase of the molding cycle where feedstock is flowing into the mold cavity under pressure from the screw.

-

Title or question

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links. -

Finishing Operations

The steps applied to a MIM component after sintering to tailor the dimensions, properties, or attributes to the application; examples include machining, polishing, heat treatment, straightening, and electroplating steps.

-

Flashing

A lip of injected feedstock that penetrates along the parting line of a die cavity due to excessive pressure, poor tool tolerances, tool/mold wear, or binder separation from the powder.

-

Flow Analysis

Computer-simulated molding is used to assess the location of the gate, runner, vent, and cooling passages, as well as other important aspects of tool design and molding, to minimize errors in production.

-

Flow Time

The time required for a powder sample to flow through an orifice in a standardized test. The flow time measures the inter-particle friction. Most powders used in MIM are not free-flowing due to the typical small particle size.

-

Fracture Toughness

A measure of the resistance to crack propagation in a material related to the applied stress when the crack starts moving and the crack size. High fracture toughness materials, such as stainless steel, provide more safety when compared with low fracture toughness materials, such as glass or ceramics.

-

Freeze Firing

A concept developed in the 1960s using water as the binder and freezing in the tool cavity. The frozen compact is ejected and subjected to sublimation to extract the water without melting the ice.

-

Gas Atomized Powder

A rounded or spherical powder formed by the disintegration of a melt stream by a high-pressure gas expansion nozzle. The particles solidify during free flight after atomization.

-

Gate

The constricted opening into the flow path at the entry to the die cavity in the injection molding tool set.

It should be the first portion of the flow path to solidify after filling the mold.

-

Gelation

A binder setting process where a macromolecule grows in a binder solution to form a highly interlinked structure with most of the binder water trapped in cells formed by the long-range molecule.

-

Gel Casting

A variant of low-pressure injection molding where the binder consists of a monomer that polymerizes in the die cavity, forming a rigid polymer to hold the particles in place, often supported by a catalyst addition just as the feedstock is molded.

-

Granulation

A term describing the agglomeration of powder or the breaking apart of lumps, runners, sprues, or parts that are reformed into pellets for reloading into the molding machine.

-

Green State

The condition of the molded component prior to de-binding or firing. The term comes from the ceramic concept of greenware in reference to formed bodies that are not sintered.

-

Green Strength

The strength of the as-molded component at room temperature.

-

Guided Wave

An in situ inspection technique involving wave propagation through a MIM compact while still

in the mold. The mathematical transform of the scattering behavior detects defects, allowing for sorting on ejection.

-

Hard Material

A group of compounds that are typically metal carbides, borides, oxides, or nitrides that exhibit a high hardness. To fabricate components, various combinations of hard materials are combined with cementing metallic phases during liquid phase sintering – for example, TiC is sintered with Ni or Fe to form a cermet.

-

Hard Metal

Like hard materials, but usually reserved for the WC-Co family of hard materials or cermets. This name for the cemented carbides is more popular in Europe, but in general, it reflects the high hardness after sintering.

-

Hardness

A formal test of resistance to penetration by a pointed or rounded indenter under a given load. There are many useful hardness tests where the depth or width of the penetration is measured. Often, this relates to other material properties, such as strength.

-

Heavy Alloy

A class of high-density alloys based on tungsten with small concentrations of alloying additions such as nickel, iron, or copper. These alloys are in the liquid phase and sintered from mixed elemental powders to create a composite material. Most of the applications are for weights, radiation shields, thermal management heat sinks, or projectiles.

-

Hot Isostatic Pressing (HIP)

A process combining temperature and high-pressure gas to fully densify a sintered MIM structure. Used only for very high-performance structures.

-

Hot Runner

A material delivery system inside the mold where the feedstock is kept hot (molten) between shots to eliminate recycle of runners and sprues. The built-in heaters and valves are coordinated with the molding machine to ensure no freezing in the flow path.

-

Impregnation

Liquid polymer filling of open pores from an external surface, used to seal open pores after sintering for improved lubrication, corrosion resistance, or machining.

-

Inconel

A variety of nickel-base alloys invented by the International Nickel Company designed for high-temperature applications, ranging from furnace components to jet engines.

-

Infiltration

The process of filling the pores of a component with a lower melting temperature metal or alloy. It is one means of forming low-cost tooling or making dense structures by molding a porous preform and filling the pores with liquid metal, such as Al or Cu.

-

Injection Molding

A hydrostatic forming technique for shaping powders using plastic binders and relatively low temperatures and pressures.

-

Inter-Particle Friction

The friction between powders that limits sliding, packing, and densification.

-

Invar

Low thermal expansion alloys of iron-nickel-cobalt where a martensitic phase transformation is balanced against the thermal expansion coefficient to give a near zero thermal expansion coefficient over a range of temperatures.

-

Irregular Powder

A powder that lacks shape symmetry in the individual particles.

-

Jetting

A condition that arises with the rapid filling of an injection mold where the feedstock shoots across the

mold and fills back toward the gate. Generally, this is unacceptable for quality components.

-

Knit Line

The same as a weld line. A linear defect occurs where feedstock streams merge in the cavity because of two gates or flow around a core or other solid portion of the die.

-

Kovar

A glass-to-metal sealing alloy used for microelectronic packaging and other situations where a matched thermal expansion or graded structure is required.

-

Low-Pressure Molding

The use of lower pressures and low-viscosity binders (largely water-based or wax-based) to fill out a complex tool cavity without packing the shape. This route is successful for components where internal flaws are not a concern, such as nozzles, spray tips, or other geometries where external geometry is the key concern.

-

Lamination

A layered structure or cracking in the pressed compact resulting from ejection stresses exceeding the green strength.

-

Liquid Phase Sintering

Sintering at a temperature where a liquid and solid coexist due to chemical reactions, partial melting, or eutectic liquid formation. It is most useful for stainless steels, tungsten, cemented carbides, cermets, and ferrous alloys containing phosphorus, boron, copper, or silicon.

-

Lubricant

An organic additive that is mixed into the feedstock to minimize die wear and aid in ejection after compaction.

-

Maraging Steel

A high strength, high toughness class of iron-nickel-molybdenum alloys that lack carbon yet form their strength by an age-hardening process in the martensitic phase. Strength levels of 4 GPa or 600 psi are possible with these alloys.

-

Martensite

The distorted ferrite crystal structure (the common variant is a distorted body-centered cubic phase that forms a body-centered tetragonal structure) due to carbon super-saturation in the rapidly cooled ferrite. Martensite is hard and brittle; hence, it is usually tempered to partially relax the hard phase for improved toughness.

-

Mean Size

The average value from the particle size distribution.

-

Mechanical Alloying

The formation of an alloy powder by milling elemental powders for a prolonged time; frequently used to create amorphous or dispersion-strengthened alloy powders via attritor milling.

-

Median Size

The centroid of the particle size distribution, where half of the particles are larger and half are smaller; not necessarily the mean, but easily identified as the 50% value. Also known as the D50 particle size.

-

Melt Index

A measure of flow at low shear strain rates, where a capillary tube is used to extrude molten feedstock under a dead load. The melt index depends on the capillary tube diameter and applied load but is always reported as the grams of feedstock collected from the tube in 10 minutes.

-

Metering

Controlled forward extrusion of molten feedstock past the screw tip and check ring to ensure the proper shot volume is ready for the next filling event.

-

Micro-Miniature

Component dimensions measured in the micrometer size range, requiring microscopes for evaluation. These are typically formed using special machines with smaller shot sizes to enable better precision for small bodies.

-

Micro-Molding

A new class of MIM technologies geared to the production of components in the millimeter and micrometer size range, requiring new technologies in tool fabrication, nanoscale powders, and molding machine operation and construction. Most of the early applications are in microelectronics, medicine, sensors, and optical communication systems,

-

Micro-Structure

Detailed information on the microscopic phases, pores, grains, defects, heterogeneities, and other property-controlling features.

-

MIM

Metal powder injection molding, where the inorganic phase suspended in the binder is predominantly a metal or alloy powder. Common engineering alloys are made possible by mixing elemental powders and forming the alloy during sintering (homogenization) or by using a pre-alloyed powder where each particle contains all of the elements. MIM is a subset of powder injection molding (MIM).

-

Mixing

The thorough intermingling of powders of two or more different compositions. It is also used to describe the compounding of feedstock by the thorough distribution of binders between particles.

-

Mold Flow Simulation

The use of computer simulations for analysis of the flow, packing, venting, sizing, cooling, and other events and tool or machine parameters associated with MIM forming operations.

-

Mold Release

A spray or coating that reduces component sticking to the die cavity, aiding ejection without defects.

-

Moldability

A relative measure of the ease of filling out a tool cavity during injection molding. It can be determined by the length of filling for a long, narrow passage. The current test of plastic moldability measures the filling of a spiral, which has been altered in MIM to a zig-zag fill test to induce powder-binder separation along the flow path.

-

Multimodal

A powder size distribution that exhibits several modes, possibly generated by blending several monosized powders.

Nanoscale – Powders or microstructures with sizes that can be measured in nanometers. Typically, the powders are less than 100 nm in size or less than 0.1 µm.

-

Near Net-Shape

Many production technologies, including MIM, attempt to form a discrete component without a need for final machining. Together, these technologies are considered net-shape approaches, but when critical dimensions cannot be held without a final machining step, they are termed near-net-shape technologies.

-

Net-Shape

A component manufactured to final density and dimensions without the need for machining. MIM is a net-shape process.

-

Newtonian Flow

An idealized viscosity situation applicable to a few fluids where there is no sensitivity to the shear strain rate, only temperature. The stress is proportional to the shear strain rate.

-

Nodular Powder

Irregular particles with knotted, rounded shapes. This is characteristic of water-atomized powders.

-

Open Pore

A pore completely through a component from one surface to another. During thermal de-binding, the pores must be opened to allow the escape of evolving vapors. Open pores close in sintering at a density near 92% of the theoretical.

-

Oxidation-Reduction

A combination of atmosphere-powder reactions that can extract oxygen (reduction) or deposit oxygen (oxidation) in a powder compact during heating, especially during de-binding and sintering. Reduction conditions are usually required for sintered metallic materials.

-

Packing Pressure

The peak pressure encountered in the molding operation once the die is filled, prior to freezing of the gate. It is precisely controlled for weight uniformity and optimized for final dimensional control.

-

Particle Size

The controlling linear dimension of an individual particle, as determined by analysis with screens, lasers, or other sensing techniques.

-

Particle Size Analyzer

An automated device for the determination of the particle size distribution. These are widely used in research, product development, and quality control functions as part of MIM to ensure repeatable powders for the process.

-

Parting Line

The linear mark (witness line) on a component where two separate tool or die pieces are mated during shaping. In injection molding, it is where the two halves of the die join together.

-

Pelleting or Pelletizing

The formation of discrete chunks of feedstock with repeated sizes and shapes that allow easy flow and filling of the molding machine.

-

PIM

Powder injection molding is the comprehensive term for forming inorganic engineered components in a plastic molding machine using thermoplastic binders and inert powders, with subsets including metal powder injection molding (MIM), ceramic powder injection molding (CIM), and cemented carbide powder injection molding (CCIM).

-

Planetary Mixer

Usually, these have two offset mixing blades that rotate around individual shafts, and the two blades further rotate around a center axis. The net effect is intermixing, stirring, and shearing to produce MIM feedstock, usually in a heated vessel.

-

Plasma De-Binding

A new technology similar to catalytic de-binding involves a low-pressure plasma for depolymerization of the binder from the sample surface inward to avoid heating and softening for distortion control.

-

Plunger Molding

A hydraulic plunger is used to push molten MIM feedstock into a die cavity, where motion and pressure are controlled by the applied hydraulic pressure.

-

Pneumatic Molding

Use of an air pressure head over molten feedstock to push it into a die cavity. This is the lowest cost and least precise form of MIM, yet it is widely employed in the fabrication of large ceramic structures.

-

Poly-Disperse

Implies a broad powder size distribution, covering a wide range of particle sizes with no clear mode size.

-

Pore Size

The size of the holes or voids between powder particles, often measured by microstructure quantification, mercury porosimetry (open pores only), or other tests that include gas flow, gas condensation, and polymer intrusion.

-

Porosimeter

A device for measuring the size of the open pores using high pressures and mercury intrusion techniques.

-

Porosity

The amount of void space in a powder compact. Most MIM materials have less than 5% porosity after sintering.

-

Powder

Particles of solid matter characterized by a small size, less than 1 mm in size. Most MIM powders are below 20 micrometers in maximum size.

-

Pre-alloyed Powder

Each particle contains an intimate mixture of two or more elements in a prescribed ratio to form an alloy; examples include brass, bronze, steel, and stainless steel.

-

Pre-sintering

The heating of a compact to a temperature lower than the normal sintering temperature to gain strength for subsequent handling, including machining. This is often performed by heating above the highest temperature required to thermally decompose any residual binder polymer.

-

Pressure-Assisted Sintering

Sintering is done with the application of external pressure. It is often performed by initially sintering in a vacuum and subsequently pressurizing the furnace to densify any remaining closed pores. It is best applied to high-performance alloys or difficult-to-sinter alloys and is commonly employed for nitrides that decompose during sintering (AlN and Si3N4) and brittle materials that require full density (WC-Co, for example).

-

Pressure Control

The final phase of molding is where the gate is not frozen, and the quantity of feedstock in the die cavity is controlled by pressure, thereby ensuring uniform weight and dimensions in the final MIM component. Proper control is achieved by monitoring pressure sensors in the die cavity wall.

-

Pseudoplastic Flow

A form of viscous flow where there is a strain rate sensitivity to the viscosity; generally, it is the opposite of dilatant flow since the viscosity decreases with higher strain rates.

-

Pycnometer

A device for measuring the theoretical density of a loose powder or preform. Helium and granular Afluids@ are commonly employed to encase the powder or component for determination of true volume, and when coupled with an independent mass determination, they lead to a density.

-

PZT

Piezoelectric ceramic based on oxides of lead (Pb), zirconium (Zr), and titanium (Ti) used for ultrasonics, sensors, sonar, and various signal propagation or collection applications based on shapes fabricated by MIM.

-

Rapid Prototype

Several techniques are emerging that bypass a need for tooling by using computer-controlled freeform fabrication to generate the first MIM green body, typically via building the feedstock into a three-dimensional object from a stack of closely spaced laminates.

-

Reciprocating Screw

Injection molding with a screw located in a heated barrel. During compression, metering, melting, and forward advance of the feedstock, the screw is turning; while during mold filling, it becomes a plunger to quickly fill the cavity.

-

Reduced Powder

Metal powder produced by the chemical reduction of a compound, most typically a metal oxide.

-

Refractory

A metal or ceramic having a high melting temperature, usually over 1700°C. Examples of refractory metals are tungsten, molybdenum, rhenium, and zirconium, while examples of refractory ceramics are alumina, zirconia, yttria, and chromium.

-

Rheology

The study of strength, elastic, plastic, and viscous flow of polymers and feedstocks used in MIM.

-

Runner

A portion of the feed path for filling an injection molding die; the runner is between the sprue and gate, the latter being the inlet to the actual die cavity.

-

Screw

The key portion of an injection molding machine for metering and filling the die cavity. It has a taper along the length to compress the feedstock as it is metered for the removal of trapped air and a check ring at the tip to allow forward plunging motion during mold filling.

-

Screw Molding

A reciprocating screw is used to mix, pressurize, deair, and convey molten feedstock to finally be injected into a tool cavity. This is the most widely employed means of injection molding precise components.

-

Secondary Operations

Those activities performed to adjust the dimensions or properties of a component after sintering. Examples include heat treatment, coining, machining, electroplating, impregnation, and shot peening.

-

Segregation

Non-uniform distribution of ingredients, such as powder separation by size, shape, or density, or chemical separation in the microstructure of a solidified material.

-

Sendust

Alloys of iron-aluminum-silicon that have important combinations of hardness and magnetic properties suitable for magnetic card readers and other high-use magnetic applications. The alloy hardness is such that MIM is the most credible manufacturing route.

-

Setter

The tray or shaped substrate for support of MIM components during de-binding and sintering.

-

Shear Rate

A measure of the rate at which feedstock is deformed and forced to flow into a die cavity. It has units of inverse seconds. Actually, it is the shear strain rate that represents the sheared change in length divided by the original length in unit time. For MIM, shear rates of several thousand per second are normal, meaning the slug of feedstock is quickly deformed to fill out the cavity.

-

Shot Size

A historical basis for sizing molding machines. This is usually given in terms of the amount of polystyrene that can be moved through the nozzle in a single forward motion of the screw or plunger.

-

Shrinkage

A decrease in dimensions of a component that occurs during sintering, usually 15% or up to 25% in a few cases and as low as 2% with multimodal powders.

-

SiAlON

A group of commercial alloys based on silicon nitride, with liquid phase formers such as alumina and yttria. These are very strong and lightweight materials with exceptional strength and reasonably high-temperature properties (up to 1200°C), useful in high-temperature aerospace, diesel engines, and military systems.

-

Sigma Mixer

A closed mixer consisting of two blades that look like the Greek capital letter sigma. These blades lift and separate feedstock to form a mixture of moderate homogeneity. A major advantage for MIM is the small batch size but with low homogeneity due to the poor shearing.

-

Silicon Carbide

The man-made compound SiC that is used for applications ranging from sandpaper to high-temperature heating elements. It has excellent high-temperature strength and oxidation resistance and is formed by MIM when complex shapes are required without post-sintering machining. Most systems rely on boron and carbon additions to improve sintering.

-

Silicon Nitride

Compositions that are based on the stoichiometric compound Si3N4; in MIM, this compound is used with various liquid phase sintering additives to form SiAlON compositions.

-

Sink Mark

A shallow surface cavity that forms during cooling. It is usually indicative of excessive wall thickness or underpacking prior to gate freezing and may be corrected by reducing the wall thicknesses or using higher molding pressure.

-

Sinter Harden

Controlled cooling from the sintering temperature is designed to induce desirable transformations and microstructures to avoid post-sintering heat treatments. Usually, it is applied to ferrous alloys to control martensite formation during cooling.

-

Sintering

The thermal process that bonds and densifies the molded powders. It increases the component strength via diffusion or related atomic-level events. Most of the mechanical, magnetic, or other properties of a MIM part are developed in the sintering cycle.

-

Sintering Diagram

A process map showing the interaction of the key variables with respect to the densification of a powder. The variables include particle size, grain size, temperature, time, and applied pressure.

-

Solids Loading

The relative powder volume in feedstock designed for binder-assisted shaping. Common injection molding feedstocks have solids loadings from 75 – 85 % powder.

-

Solvent De-Binding

The extraction of the binder or some portion of the binder by leaching into a solvent. This is performed by immersion or exposure to solvent vapors. The solvent might be flammable, toxic, or simply water or ethanol.

-

Speed Control

That initial portion of the molding cycle where feedstock is flowing to fill the mold cavity and no feedback signals are available; thus, the molding machine is simply controlled by the position of the screw during its forward (injecting) motion.

-

Spherical Powder

Powder with a uniform spherical shape and a size that can be characterized by a diameter.

Gas atomized powders are often spherical.

-

Sprue

The initial inlet into the die set for injection molding feedstock. The sprue is usually filled by the nozzle and is tapered for easy extraction after mold filling. It feeds the runner system, which in turn feeds the gate.

-

Stainless Steel

A wide range of alloys based on iron and chromium that give corrosion resistance in most common corrosive environments. The most popular MIM alloys are 300 series (austenitic) that contain high nickel levels, 400 series (mostly ferritic or heat treatable into martensitic) that have little nickel, and precipitation hardened alloys (mostly heat treated into martensitic) such as 17-4 PH.

-

Stereolithography

A group of rapid prototype techniques that construct a green MIM component from a computer design by building thin sequential layers that match cross-sections through the design, typically using laser, inkjet, cutting, or micro-nozzle concepts.

-

Stress Relaxation

The removal of residual stresses in a MIM component by controlled cooling or reheating to relax the polymer entanglement or other sources of stress.

-

Super-Alloy

The highest-performance alloys used for the most demanding applications. Typically, these are formulated with a wide range of components based on nickel, with tailored properties that allow use in moving components in jet turbines.

-

Super-Critical Extraction

The use of high pressure and moderately high temperatures to heat a solvent over the critical point for binder removal. The most common super-critical fluid used in MIM is carbon dioxide. Over the critical point, the gas is compressed to a density equal to that of the liquid, so there is no volume change during binder removal.

-

Super-Solidus Sintering

A liquid phase sintering process applied to pre-alloyed powders where sintering occurs over the solidus temperature, thereby nucleating liquid within the particles to enable rapid densification of larger particles. It is used for high alloy systems, such as tool steels, stainless steels, cobalt-chromium alloys, and super-alloys.

-

Surfactant

A surface active agent added to the binder system in MIM feedstock to induce binder wetting of the powder surface. There are many trade secrets, but most powders prove responsive to simple soap compositions.

-

Tap Density

The density of a powder obtained when it is vibrated for a prolonged period. The tap density represents the highest packing density possible for a powder without the application of pressure.

-

Tensile Strength

The maximum strength attainable prior to failure during uniaxial tension testing; properly known as the ultimate tensile strength, but often given as the tensile strength.

-

Thermal De-Binding

Extraction of the polymer in de-binding by the application of heat. The classic processes relied on slow heating in air to evaporate the binder over a period of days.

-

Thermo-Gravimetric Analysis

A term that means measuring the sample weight change versus temperature during heating. It is used for the determination of polymer evaporation temperatures by performing constant heating rate experiments and recording the sample weight versus temperature.

-

Thermoplastic

Binders or polymers (like wax) that soften on heating but stiffen on cooling and can repeat the heating and cooling process without undergoing degradation.

-

Thermosetting

Binder or polymer hardening due to heating to a temperature where cross-links form between the polymer chains. Unlike a thermoplastic that can be softened by reheating, a thermosetting binder becomes hard on the first heating cycle and cannot be subsequently softened.

-

Thixo-Molding

A direct injection molding technique that is a hybrid between powder injection molding and die casting. The alloy is partially melted to form a solid-liquid mixture that is initially stiff but, with continued stirring, becomes low in viscosity and easily molded. Many MIM operations had hoped for an aligned benefit for thixo-molding lower-temperature alloys and lighter-weight alloys. Currently, only magnesium alloys are commercial, but aluminum and titanium variants have been demonstrated.

-

Thixo-Tropic

A material flow behavior where there is a yield strength that must be overcome to initiate flow, and with shear, the viscosity decreases; however, during aging, weak bonds form to increase viscosity.

-

Torque Rheometer

A computerized mixer that allows interactive experiments to measure the torque for mixing as various changes are made in surfactants, powders, binders, temperature, or shear rate. The output from the torque rheometry provides an effective basis for the formulation of MIM feedstocks.

-

Toughness

Literally the energy to cause failure or fracture per unit of test material cross-sectional area. It can be estimated by the product of strength and ductility but is more typically measured using a swinging pendulum that fractures a standard test sample (Charpy test). The kinetic energy loss by the pendulum is the toughness. In design, the most important parameter is fracture toughness, which measures the stress required to cause a crack to propagate.

-

Transverse Rupture Strength

Three-point fracture test applied to brittle materials or green compacts to assess relative strength. The three-point bend test configuration is most common for these materials with a four-point test sometimes used to measure the strength of sintered ceramics.

-

Twin Screw Processor

A mixer or extruder consisting of two intermeshing screws which convey, shear, and mix a powder or powder-binder mixture during transport through the mixer.

-

Ultimate Tensile Strength

The highest engineering stress encountered in the tensile testing of an engineering material.

-

Ultrasonic Inspection

The use of high-frequency sound waves for the detection of cracks or other defects. The most common procedure uses through or back transmission waves out of the die cavity, but new technology allows guided wave inspection in the die cavity during molding.

-

Vacuum De-Binding

A variant of thermal de-binding that extracts the binder by progressive heating in a vacuum to distill the molten binder out of the powder compact. Usually, vacuum de-binding is performed with a gas inlet to drag the escaping binder to the pumps.

-

Vent

The thin channel in a toolset that allows air to escape while molten feedstock enters through the gate. It is located opposite the gate or in extended features of the part design and should not be sealed until late in the molding cycle to avoid trapped air pockets in the component.

-

Viscosity

The resistance to flow of a feedstock or polymer. Formally, it is the proportionality between the stress and applied shear strain rate. A high viscosity makes molding difficult. A low viscosity is easier to mold, but there are often difficulties with flashing.

-

Water Atomized Powder

Irregular or ligamental particles formed by impacting a molten metal stream with high-pressure water.

-

Water-Based Binder

Mostly gelation binders that become rigid after molding by the formation of a long-range molecule with water in the structure. Other forms rely on water saturated with silicates that form glasses on freezing.

-

Water Soluble Binder

A class of binders that rely on polymers that are water soluble, so solvent de-binding takes place in water. The most common are polyethylene oxide, polyvinyl alcohol, and polyethylene glycol.

-

Wax-Polymer

A general term for polymers used as binders that consist of low molecular weight polymers and wax fillers. The polymers are usually simple molecules such as polyethylene, polypropylene, or co-polymers such as ethylene vinyl acetate. These are the classic binders used in MIM processing.

-

Weld Line

A linear defect or mark on a compact surface where two portions were bonded, either in molding or subsequently, such as in sinter bonding.

-

Weibull Modulus

A statistical parameter associated with the spread in fracture strengths for ceramics. A high Weibull modulus indicates a narrow spread in strength and few manufacturing defects.

-

Wicking De-Binding

A method of binder extraction, especially for wax-based binders, where the component is packed in wicking powder and heated to a temperature where the wax melts. The molten wax flows by capillary action into the surrounding packing powder and leaves the component supported as the polymer is extracted.

-

Yield Strength

The end of the linear elastic region for most metals. The yield strength is the highest stress a structure can endure without permanent deformation and should be the maximum stress used in engineering designs.

-

Youngs Modulus

The elastic modulus expresses the proportionality between stress and strain during elastic deformation prior to permanent deformation; it is calculated assuming linear behavior by dividing the applied stress by the strain and for metals such as steel can range near 200 GPa (30,000,000 psi).

-

YTZ

Yttria toughened zirconia, where a few percent of Y2O3 is added to ZrO2 to help in phase stabilization such that a phase transformation occurs in the zirconia under severe stress, such as at a propagating crack tip, to block fracture.

-

Zeta Potential

An electrochemical measure of the surface charge or surface chemistry of a fine powder in a suspension.

-

Zirconia

A stoichiometric compound of zirconium and oxygen in the ratio ZrO2. It is often phase stabilized by adding other ceramics. It is widely employed as a MIM material because of its exceptional wear resistance and difficulty in grinding. It is also colored to form a wide variety of semiprecious jewelry items.

CONTACT DETAILS

Phone: (651) 257-3143

Email: sales@smithmetals.com

Address: 15045 Per Rd, Center City, MN 55012

CERTIFICATIONS

- ISO 9001

- ISO 13485

- FFL

- ITAR

Write your caption hereButton

Write your caption hereButton Write your caption hereButton

Write your caption hereButton