Smith Metal Products Blog

Jim Beyer, Account Manager

Smith Metal Products, A Division of Plastic Products Company

Attention appliance designers – a smart material option is creating new possibilities for appliance component manufacturing. It’s a material process often overlooked in the appliance industry but offers many metal options, has intricate and complex design opportunities with many attractive finish choices and repeatable precise quality. It conserves metal material compared to other processes, has turnaround time advantages in medium and large quantities while ensuring significant cost savings. That design option is metal injection molding (MIM).

Smith Metal Products produces MIM parts from ID as small as 0.010″ and OD as small as 0.060″ up to lengths of 3.00″ by 0.25″ thicknesses.

Why MIM And Why Now?

Driven by constantly changing consumer preferences, the appliance industry has never been more demanding of innovation for functionality, appearance, quality and economy. Like automobiles and smart phones, appliances have a “new look” every year and with it, new functions including newly engineered operating features as well as new exterior cosmetics. To stay ahead of this curve, appliance designers should look to MIM as a favorable option for design enhancements. Once thought of as a radical method for making metal parts, MIM is now an accepted and widely used process in demanding industries such as aerospace, automotive and medical. MIM’s time has arrived for the appliance industry.

Where outside component suppliers to the appliance industry over the years consisted mostly of metal fabricators, plastic molders and precision machine shops, alternate metal processors have arrived on the scene. Leading these are MIM specialists with the technology, experience and large scale capabilities positioned to take center stage. Here’s how:

Metal Injection Molding (MIM) Technology Has Come Of Age

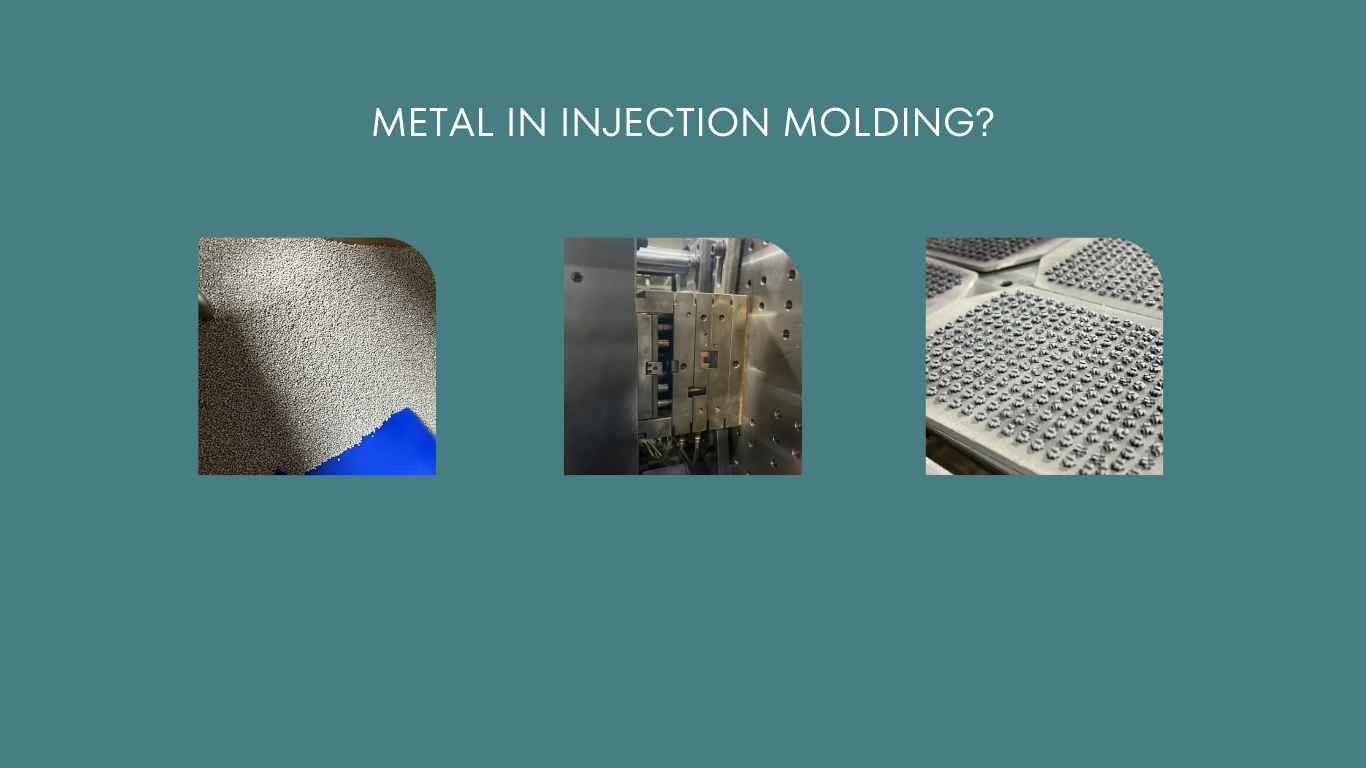

Metal injection molding (MIM) is a net-shape molding process for producing solid metal parts that combines the design freedom of plastic injection molding with superior material properties near that of wrought metals.

Dedicated Smith Metal Products MIM facility has newest, high capacity molding machines and continuous debinding and sintering furnaces. All on-site, needed support equipment includes mold-making, laser etching/engraving, inspection lab and more.

Metal injection molding mixes metal powder with a thermoplastic binder and is molded into a cavity. The molded part is thermally processed (sintered) removing the binder while producing a net shaped, high density component. Because it is a molding process, it is capable of producing an almost limitless array of highly complex three dimensional geometries in many different metal alloys. It is a very good option for cost-effective medium to high volume part production.

Compared to machined and cast parts that require finishing operations, MIM customarily costs far less per unit, offers greater design flexibility, is a much faster process in large quantities and provides precise and highly repeatable quality. MIM materials that are ideal for appliance applications include various grades of hardened steel, stainless steel, nickel-based alloys, ceramics and many others.

With these advantages and design freedom, MIM provides benefits for a large range of possible appliance related component applications including valves and valve lifters, connectors, locks, hinges, handles, supports, gears and many other appliance components including multiple parts combined efficiently molded into a single component.

What Are MIM’s Advantages Over Other Processes?

For many years, appliance manufacturers have used powdered metallurgy, plastic molding and precision machining processes in their designs. A comparison reveals several advantages for MIM:

MIM parts provide cosmetic appeal and have the necessary strength required by the application. Shown is a handle made from stainless steel.

MIM is a superior process to powder metallurgy (PM) because MIM parts have greater metal density and three times the fatigue strength. MIM parts tensile strength is consistent with the metal selected for the process. Also, PM is limited to 2D features while MIM allows complex geometry including undercuts, holes perpendicular to the main axis and precision 3D features.

MIM is often a superior process to precision machining. Each machined feature adds time and cost to the part price. When excess material is left in the part to save time and removal cost, excess weight is retained. In contrast, MIM parts can have many features incorporated into the tooling with excess material cored out, saving manufacturing time, material, part weight and money in the final component cost.

MIM is superior to plastic components because MIM parts are conductive, magnetic, strong, stiff, tough, chemically resistant and can operate at temperatures far over the melting range of most polymers.

Recognizing Good Appliance Part Candidates

MIM should be considered when part production quantities are over 10,000 pieces, are an appropriate size range, have complex shape, require material performance and necessitate reduced cost. MIM almost always has a cost advantage where the shape complexity is outside the range of the other manufacturing processes previously described.

Electronic components can be great MIM candidates with excellent mechanical properties such as micro-switches, connectors, solenoids, heat sinks, optic connectors and distribution frames.

Part size is important because MIM is not a large part process. Parts measuring 3 inches in all directions or smaller and weigh 25 grams or less are the best MIM candidates. Combining multiple parts into a single component (assembly) is often possible with MIM to eliminate screws, adhesive bonding, soldering, welding while reducing both weight and the cost of multiple components. Light-weighing is a long-term appliance design goal. Refrigerators, stoves and dishwashers are large, heavy to assemble, ship and install. The MIM process can help lighten that load.

Shape complexity is an area where MIM is strongest. MIM is often specified for components ranging from 20 specifications (dimensions, locations, surface finish, material density, etc.) on the design drawing to over 250 specifications. Surface finish flexibility is one of MIM’s many specification features attractive to appliance designers. From matte, stainless steel and highly polished surface finishes and color shades, there’s everything cosmetically that a designer could envision that’s possible and practical when specifying MIM.

MIM Turnaround Time

Appliance manufacturing cycles are tight with demands for just-in-time delivery required from part suppliers. MIM suppliers are in tune with demanding production and delivery schedules with experience in aerospace, automotive and medical industries. So naturally requirements for appliance manufacturers can be met equally as well.

Every MIM project begins with mold design and build which can take up to 16 weeks. Once the tooling is set, manufacturing time for batch quantities of 2,500 and higher usually can be accomplished in 4 weeks or less for “as sintered” parts.

The appliance designer should think in terms of the initial mold cost and the price of a one year quantity of parts. Then amortize both over the projected design life of that part. With a minimum annual requirement of 10,000 pieces for starters, the appliance manufacturer can easily specify quarterly part quantities and delivery with an anticipated 4-week lead time. Releases should run at no less than 2500 to 3000 parts with three or four releases a year. Compared to both inside or outsourced precision machining for needed parts, this type of MIM relationship is far more consistent and reliable both in terms of quality, price and on-time delivery.

The Appliance Designer Challenge – More MIM Awareness

Staying up-to-date with MIM progress is a worthwhile investment for today’s appliance designer. Access to the latest information has never been easier available on the Smith Metal Products website, from the North American Metal Injection Association and the Metal Powder Industry Federation as well as other sources through a Google search.

Request a quote, Part Evaluation, or call us today at 651-257-3143.

CONTACT DETAILS

Phone: (651) 257-3143

Email: sales@smithmetals.com

Address: 15045 Per Rd, Center City, MN 55012

CERTIFICATIONS

- ISO 9001

- ISO 13485

- FFL

- ITAR

Write your caption hereButton

Write your caption hereButton Write your caption hereButton

Write your caption hereButton