Smith Metal Products Blog

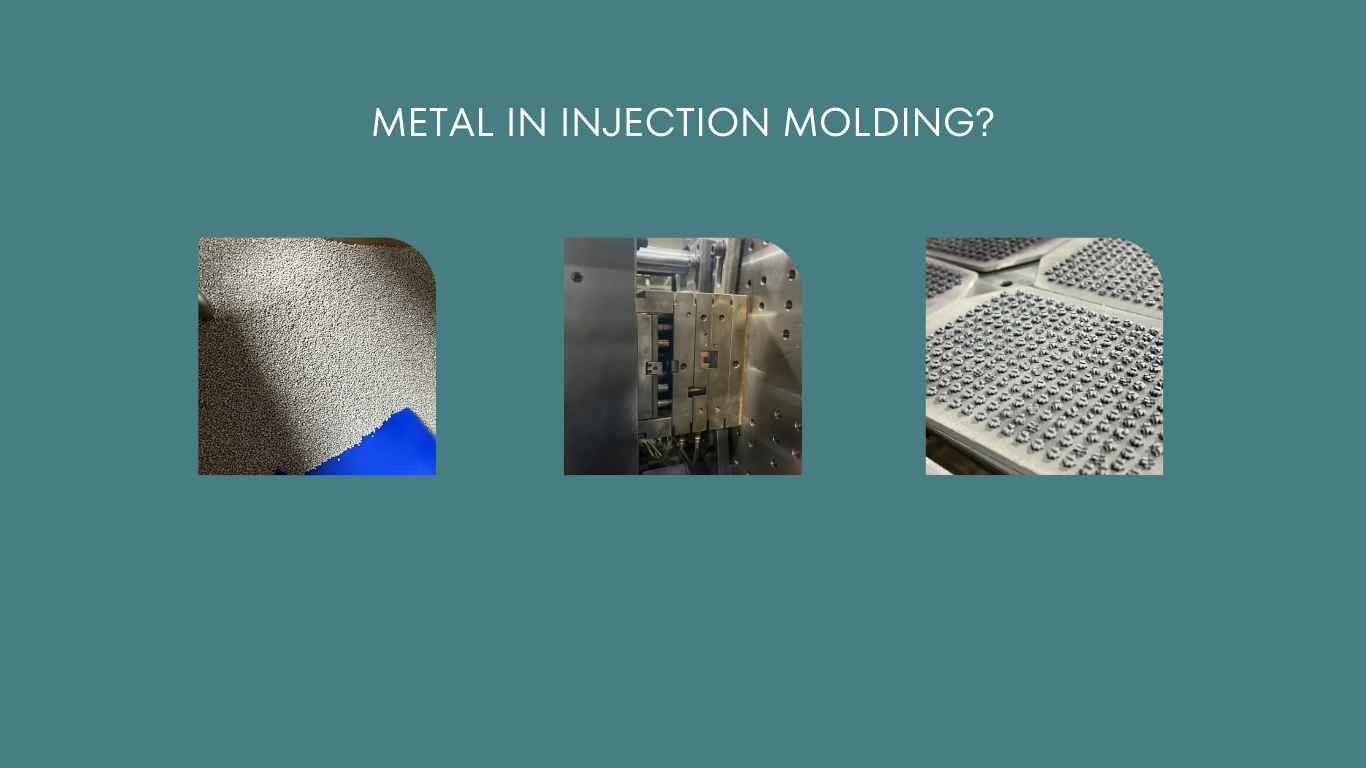

When does it make more sense to use outsourced MIM part production than to buy and operate a machining center and do the work in-house? MIM is metal injection molding. It is an alternative process instead of machining parts out of raw metal stock. Many original equipment manufacturers of firearms and defense products are mandating that their part suppliers outsource to secure price advantages while maintaining strict quality requirements.

With price pressures and quality requirements getting more stringent by the day, MIM often is the answer. This brief article provides a simple analysis for making the choice to insource or outsource.

A New Or Existing Part Project Requires A Process Evaluation

Starting with the premise that an existing or new part project requires a process evaluation, the following considerations enter the picture. Foremost is an answer to this question – is your part project a viable MIM candidate? Metal injection molding often is a more effective process to achieve precision parts while eliminating machining. That’s because MIM parts are precise, net shaped parts that are produced faster, and usually with no secondary operations. But not all parts qualify for this highly cost-effective alternative solution. Check the following to see if your production application meets these criteria:

Annual volumes of 10,000 pieces or more (the more the better).

Under 100 grams/3.5 ounces finished part weight.

All dimensions of the component 3 inches or less.

Maximum wall thickness of 3mm (0.125 inch) or less (or cored out to this thickness).

Must be ferrous metals (no aluminum, copper, brass, zinc, or magnesium).

Medium to high complexity.

Possibility of merging multiple component assemblies into one part.

Possibility of reducing part weight and/or increasing part strength.

Smith Metal Products Cost Comparison for Machined part versus MIM part:

CNC Part: $8.25 Each

MIM Part: $2.50 Each

$825,000 for machine, labor, etc. $100,000 for 4 molds (average mold cost is $20,000)

100,000 pieces machined (4 parts 25,000 each) $150,000 for 100,000 pieces molded (4 parts 25,000 each)

Year 1 $825,000 or $8.25 per part Year 1 $250,000 or $2.50 each

Not included in the above comparison is what a machining center is costing your company when not making parts. That’s a big cost factor to include in every analysis. By comparison, when outsourcing using MIM production, you pay only for the parts ordered, not for idle machine time or other related downtime experienced with in-house production.

Remember, the above is a generalization and serves as a starting point. Every process application is different. But the numbers above are based on 20 years experience making MIM parts at Smith Metal. So the formula is a valid one.

Also, a MIM supplier has part and mold design experience that can reduce per part cost even more. And by using a USA based MIM supplier like Smith Metal, good jobs are created and kept where they belong – here at home.

Request a quote, Part Evaluation, or call us today at 651-257-3143.

CONTACT DETAILS

Phone: (651) 257-3143

Email: sales@smithmetals.com

Address: 15045 Per Rd, Center City, MN 55012

CERTIFICATIONS

- ISO 9001

- ISO 13485

- FFL

- ITAR

Write your caption hereButton

Write your caption hereButton Write your caption hereButton

Write your caption hereButton