Smith Metal Products Blog

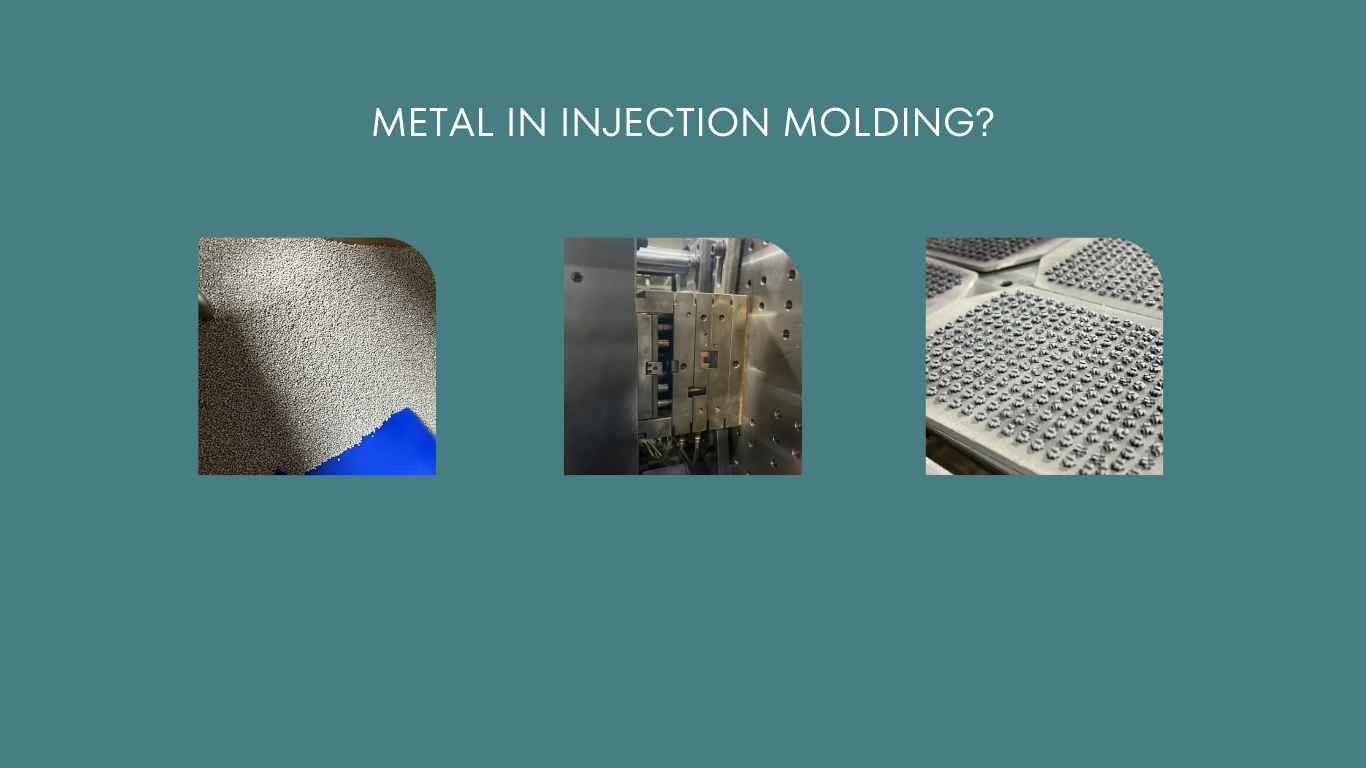

Smith Metal Products specializes in metal injection molding (MIM) of soft metal alloys and an array of other metals for small electronic and electrical components.

Ideal for the fast-changing needs of the telecom and electronic markets, Smith Metal Products MIM processes utilize the latest technology that are built around an automated production process. Parts begin when metal powder is suspended in a binder or feed stock which is then injection molded into a tool. The part then goes through a debinding and sintering process to form a full dense metal part. The result are parts that are very precise, net-shaped and can be produced faster than machining and usually with no secondary operations.

Smith Metals specializes in manufacture of many electrical/electronic components including: high voltage power connectors, PCB terminal blocks, smart phone components, solenoids, micro switches, heat sinks, microwave, filter and switching components as well as components for NEMA rated enclosures plus many more.

Costs for Smith Metal components are often up to 50 percent less than other part making processes, highly important in today’s competitive electrical/electronic markets. Faster too. With fewer setups coupled with the speed of metal injection molding, turnaround time from concept to component completion can save weeks of waiting time.

What are the ideal part parameters for the MIM process? Parts most suitable include those made from a full range of alloy materials, including soft metal, stainless steels and Titanium. Ideal parts have simple to complicated geometries and a finished part weight of less than 100g (3.5 oz). All dimensions of the component should be 3 inches or less with a maximum wall thickness of 3 mm (0.125 in.) or less. Annual volume requirement for efficiently produced and priced electrical and electronic components is 10,000 parts or more.

Part designers note: Program Management is an important element in Smith Metal’s MIM processes. This includes complete process engineering, designing and implementing automation, quality assurance, assembly, packaging, product fulfillment and distribution.

Request a quote, Part Evaluation, or call us today at

651-257-3143.